Feed barley, a byproduct of the malting and extraction process, is considered one of the most popular and nutritious food industry wastes in animal nutrition. Barley malt for livestock not only reduces the production costs of meat and milk but is also an effective step toward environmental preservation and sustainable agriculture.

Barley spent grain (also known as brewers’ spent grain or malt sprouts) is a byproduct of non-alcoholic beer (Ma-al-Shaeer) and malt extract factories. When germinated barley grains (malt) are cooked to extract sugar and starch, a portion of the grain’s structural materials remains, which is called “spent grain.” This product is available in the market in two forms: wet (high moisture) and dry. Due to its high protein and fiber content, it holds a special place in the rations of dairy and beef cattle.

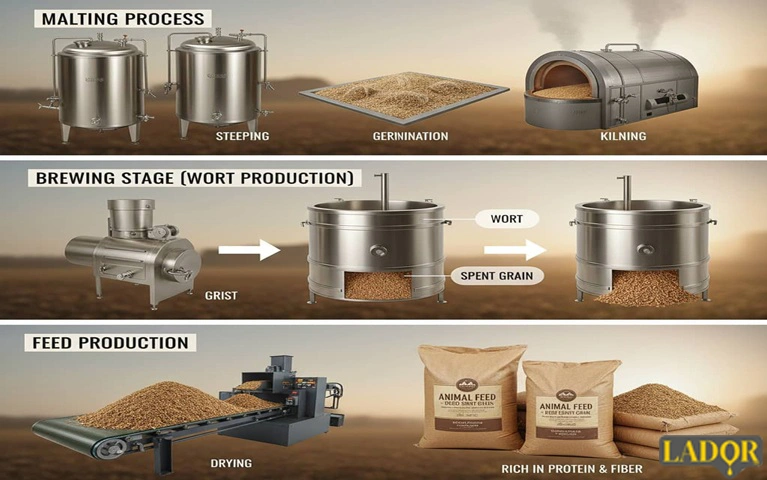

Soaking and Germination: Barley grains are moistened to germinate, activating their enzymes (converting them into malt).

Mashing and Extraction: The milled malt is mixed with hot water to convert its starch into soluble sugars.

Separation: The sweet liquid (wort) is separated, and what remains in the filters is the wet barley spent grain.

Secondary Processing: For longer shelf life, this spent grain may be dried in a kiln and produced in the form of powder or pellets.

The composition of this substance is such that it serves as a valuable “semi-concentrate.” Below is an analysis of its main components based on Dry Matter (DM):

This is the most critical part of barley spent grain. Its protein content typically ranges between 20% to 28%.

Special Feature: A significant portion of this protein is “Bypass Protein.” This means it does not degrade in the rumen and is absorbed directly in the small intestine, which is vital for increasing milk production and muscle growth.

Feed barley is rich in structural fibers essential for ruminant rumination:

NDF (Neutral Detergent Fiber): Approximately 40% to 50%. This fraction helps maintain rumen health and prevents acidosis.

ADF (Acid Detergent Fiber): Approximately 15% to 25%. This value represents the parts of the plant that are more difficult to digest but are useful for stimulating digestive tract movements.

The fat content in barley spent grain averages between 6% to 10%. These fats are a concentrated source of energy and ensure that milk fat levels do not drop in dairy cows. They also contribute to the product’s palatability.

The energy of this product is estimated at approximately 2.5 to 2.8 Mcal/kg. Although its starch is extracted during the malting process, the fat and digestible fiber found in the hull effectively provide the energy required by the livestock.

The mineral profile of barley spent grain requires careful management:

Phosphorus: The phosphorus level is very high (around 0.6%), which is beneficial for fertility and bone health.

Calcium: The calcium level is relatively low (around 0.3%). For this reason, calcium supplements must be used in the ration to balance the calcium-to-phosphorus ratio.

Barley malt is a good source of B-group vitamins, which increase in quantity during the barley germination process (malting). These vitamins help improve the metabolism and immune system of the livestock.

Despite the numerous benefits, a few points are essential:

Wet spent grain molds quickly due to high moisture (70-80%). It must be consumed within 3 to 7 days or stored as silage.

Because of its high phosphorus content, mineral balance must be maintained by adding calcium supplements or calcium carbonate to the ration.

Aala oil Sepahan Factory, operating under the brand name Lador, is a pioneer in the production of powders, oils, and raw materials for livestock and poultry feed. Some of the Ladorfat products include: rice bran for livestock, olive meal, date pits, Aleppo cattle oil, hydrogenated poultry oil, processed soybean oil, and more.

Feed barley is an exceptional protein and fiber supplement that serves as a bridge between economy and quality in animal husbandry. The proper use of this product not only reduces the costs of purchasing expensive inputs but also significantly increases herd productivity due to its high palatability and nutritional value. With correct storage management (especially in its wet form), this product is one of the best options for replacing a portion of grains in the ration.

For information on pricing and to receive expert advice, please contact the Ladorfat specialists. Thank you for your time and consideration.